Start a 3D Printing Business: Your Step-by-Step Guide

So, you're thinking about diving into the world of 3D printing and starting your own business? Awesome! It's an exciting field with tons of potential. But where do you even begin? Don't worry, this guide will walk you through all the steps you need to take to turn your 3D printing dreams into a reality.

Is a 3D Printing Business Right for You?

Before you jump in headfirst, let's take a moment to see if this is really the right path for you. Starting any business requires dedication, but 3D printing comes with its own unique set of challenges and rewards. Are you ready to learn new software, troubleshoot technical issues, and stay on top of the latest advancements in the field? If the answer is yes, then keep reading!

Assessing Your Skills and Interests

Think about what you enjoy doing. Are you a creative problem-solver? Do you like tinkering with technology? Are you passionate about design? A successful 3D printing business owner needs a blend of technical skills, creative thinking, and business savvy.

Understanding the Market

Who are you going to sell to? What problems can you solve with 3D printing? Researching your target market is crucial. Are you going to focus on creating custom prototypes for engineers, designing personalized gifts for consumers, or manufacturing specialized parts for other businesses? Knowing your market will help you tailor your services and marketing efforts.

Laying the Foundation: Planning and Preparation

Okay, you've decided to take the plunge. Now it's time to get down to business (literally!). A solid plan is your best friend.

Crafting a Business Plan

A business plan is like a roadmap for your company. It outlines your goals, strategies, and how you plan to achieve them. Key elements include:

- Executive Summary: A brief overview of your business.

- Company Description: Details about your business structure, mission, and values.

- Market Analysis: Research on your target market, competition, and industry trends.

- Products and Services: A description of what you'll offer.

- Marketing and Sales Strategy: How you'll reach your customers and generate revenue.

- Financial Projections: Estimated startup costs, revenue forecasts, and profitability analysis.

- Management Team: Information about you and any partners or employees.

Securing Funding

Starting a 3D printing business requires capital. Here are a few options to consider:

- Personal Savings: The most common way to fund a small business.

- Loans: Small business loans from banks or credit unions.

- Grants: Government or private grants for entrepreneurs.

- Crowdfunding: Platforms like Kickstarter or Indiegogo to raise money from the public.

- Investors: Angel investors or venture capitalists who provide funding in exchange for equity.

Choosing a Business Structure

You'll need to decide on a legal structure for your business. Common options include:

- Sole Proprietorship: Simple to set up, but you're personally liable for business debts.

- Partnership: Similar to sole proprietorship, but with multiple owners.

- Limited Liability Company (LLC): Offers liability protection and tax flexibility.

- Corporation: More complex, but provides the best liability protection.

Equipping Your Workshop: Choosing the Right 3D Printer

This is where things get exciting! Selecting the right 3D printer is crucial for the success of your business.

Types of 3D Printers

- Fused Deposition Modeling (FDM): The most common type, using plastic filament. Affordable and versatile.

- Stereolithography (SLA): Uses liquid resin and UV light to create highly detailed prints. More expensive than FDM.

- Selective Laser Sintering (SLS): Uses powder materials and a laser to create strong, functional parts. Typically used for industrial applications.

Factors to Consider

- Print Volume: The maximum size of objects you can print.

- Material Compatibility: What materials can the printer use?

- Print Resolution: The level of detail the printer can achieve.

- Speed: How quickly the printer can produce objects.

- Reliability: How often the printer breaks down.

- Cost: The initial price of the printer, plus ongoing maintenance and material costs.

Here's a table to help you compare different 3D printer types:

| Feature | FDM | SLA | SLS |

|---|---|---|---|

| Material | Plastic Filament | Liquid Resin | Powder Materials |

| Detail | Good | Excellent | Very Good |

| Strength | Moderate | Moderate | High |

| Cost | Low | Medium | High |

| Best For | Prototyping, Hobbyists, Education | Detailed Models, Jewelry, Dental | Functional Parts, Manufacturing |

Software and Design Tools

You'll also need software for designing and preparing 3D models. Popular options include:

- CAD Software: Tinkercad (free, beginner-friendly), Fusion 360 (free for hobbyists), SolidWorks (professional).

- Slicing Software: Cura (free), Simplify3D (paid).

Setting Up Shop: Operations and Logistics

With your equipment in place, it's time to focus on the day-to-day operations of your business.

Workflow Management

Develop a system for managing your orders, designs, and printing processes. This could involve using project management software or simply creating a detailed spreadsheet.

Quality Control

Establish standards for quality control to ensure consistent results. This includes inspecting prints for defects, calibrating your printer regularly, and using high-quality materials.

Post-Processing Techniques

Learn techniques for finishing your prints, such as sanding, painting, and assembling multi-part models. This will enhance the appearance and functionality of your products.

Spreading the Word: Marketing and Sales

Now that you're up and running, it's time to attract customers!

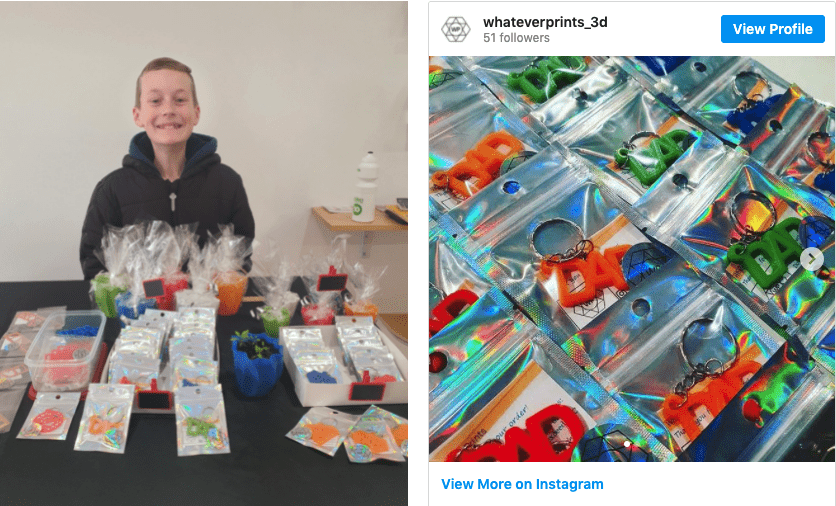

Building an Online Presence

- Website: Create a professional website showcasing your services and portfolio.

- Social Media: Use platforms like Instagram, Facebook, and LinkedIn to connect with potential customers.

- Online Marketplaces: Sell your products on platforms like Etsy, Shapeways, or Amazon.

Networking and Collaboration

Attend industry events, join online communities, and connect with other businesses in your niche. Collaboration can lead to new opportunities and partnerships.

Pricing Strategies

Determine your pricing based on factors like material costs, printing time, design complexity, and market rates. Consider offering discounts or promotions to attract new customers.

Staying Ahead of the Curve: Continuous Learning

The world of 3D printing is constantly evolving, so it's important to stay up-to-date with the latest trends and technologies.

Following Industry News

Read industry blogs, magazines, and attend webinars to learn about new materials, software, and printing techniques.

Experimenting with New Technologies

Don't be afraid to try new things! Experiment with different materials, printing settings, and post-processing techniques to expand your capabilities.

Seeking Feedback

Ask your customers for feedback on your products and services. Use this feedback to improve your offerings and stay ahead of the competition.

FAQ Section:

Q: How much does it cost to start a 3D printing business?

A: The cost varies depending on the type of printer you choose, the scale of your operations, and your marketing budget. You can start with a basic FDM printer for a few hundred dollars, but a professional-grade setup could cost several thousand.

Q: What are the most profitable 3D printing applications?

A: Custom prototypes, personalized gifts, and specialized parts for niche industries tend to be profitable. However, success depends on your market research and marketing efforts.

Q: Do I need a degree to start a 3D printing business?

A: No, a degree is not required, but technical skills and business knowledge are essential. You can learn through online courses, workshops, and hands-on experience.

Q: How do I protect my 3D designs from being copied?

A: Consider using watermarks, encryption, or legal agreements to protect your intellectual property. You can also explore patents for unique designs or inventions.

Q: What are the biggest challenges in the 3D printing industry?

A: Some challenges include high initial investment costs, competition, material limitations, and the need for specialized skills. Overcoming these challenges requires careful planning, continuous learning, and a strong focus on customer satisfaction.

Conclusion:

Starting a 3D printing business can be a rewarding venture if you're passionate, dedicated, and willing to learn. By following these steps and staying adaptable, you can turn your 3D printing dreams into a successful reality. So, what are you waiting for? Get printing! And don't forget to share your journey and successes with us in the comments below. We'd love to hear from you!